Understanding How Your Electric Parking Brake Works

The electric parking brake (EPB) is a modern evolution of the traditional handbrake. Instead of using a lever and cable, an EPB relies on electronic control units and small motors to activate the brake pads or shoes. This setup offers greater convenience and allows for integration with other vehicle safety systems, but it also introduces new troubleshooting challenges.

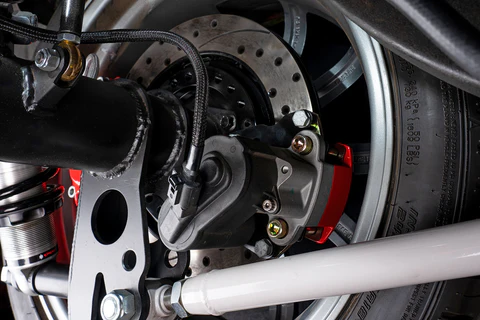

Knowing the main components—such as the actuator motor, the electronic control unit (ECU), and the brake caliper—helps you identify where issues might occur. EPB systems are designed for reliability, but electrical faults or mechanical wear can affect their performance and safety.

- Actuator Motor: Typically rated to last over 100,000 cycles under normal use.

- Control Unit: Should operate within a voltage range of 11–14V.

- Brake Pad Thickness: Replace pads when below 3 mm for optimal performance.

- System Response Time: The EPB should engage or release within 2–4 seconds.

Common Problems with Electric Parking Brakes

Several issues can affect the performance of an electric parking brake. The most frequent problems include failure to engage or release, warning lights on the dashboard, and unusual noises during operation. These often stem from electrical faults, worn friction materials, or mechanical binding in the caliper.

Understanding these problems in technical terms helps with effective troubleshooting. For example, friction material formulation—the composition of the brake pad—directly impacts how well the EPB holds the vehicle, especially on an incline. The wrong formulation may lead to slippage or increased wear.

- Warning Light: Indicates a possible fault in the control unit or actuator motor.

- Unusual Noise: Grinding or clicking may signal worn pads or a stuck caliper.

- Failure to Engage: Often caused by low voltage or damaged wiring.

- Sluggish Release: May result from corroded mechanisms or electronic errors.

Warning Signs

- Dashboard warning icon for the electric parking brake remains lit after starting the vehicle.

- Noticeable decrease in holding power, especially on slopes exceeding 10%.

Diagnosing Noise, Vibration, and Harshness (NVH) Issues

Electric parking brakes can sometimes create noise or vibration during operation. This is often linked to the NVH (Noise, Vibration, and Harshness) characteristics of the system. Factors such as pad wear, improper friction material, or uneven rotor surfaces can make the EPB noticeably louder or less smooth.

Proper noise and vibration control is essential for comfort and safety. Choosing brake pads with advanced damping layers or precision-engineered backing plates can result in a quieter, more enjoyable driving experience. Regular inspections help catch these issues early.

- Acceptable Pad Wear: Pads should be replaced when thickness drops below 3 mm.

- Noise Level: Normal EPB operation should not exceed 60 dB in-cabin.

- Rotor Condition: Check for runout greater than 0.1 mm as this can increase vibration.

Warning Signs

- Squealing or grinding sounds during EPB engagement or release.

- Vibration felt through the seat or floor when the brake is applied.

Temperature Stability and Wear Behaviour

The temperature stability of your EPB components is crucial, especially if you drive in demanding conditions. Brake pads and actuators are designed to operate reliably between -30°C to 350°C. Exceeding these limits may cause accelerated wear or even failure of electronic components.

Wear behaviour describes how quickly brake pads and other parts lose material over time. Using friction materials engineered for stable wear rates ensures consistent performance and longer service intervals. Regularly monitoring pad thickness and actuator health can prevent unexpected breakdowns.

- Temperature Range: Components should function between -30°C and 350°C.

- Typical Pad Lifespan: Most EPB pads last between 40,000 and 70,000 km.

- Actuator Inspection Interval: Check every 20,000 km for signs of corrosion or binding.

Steps to Troubleshoot Your Electric Parking Brake

Troubleshooting your electric parking brake involves both electronic and mechanical checks. Start by scanning for diagnostic trouble codes (DTCs) using a compatible scan tool, as these codes can pinpoint issues with the control unit or actuator. Next, visually inspect the wiring harness, connectors, and brake components for signs of wear, corrosion, or damage.

If you suspect worn brake pads or binding calipers, measure pad thickness and check for smooth movement. Always follow the manufacturer’s specifications for component limits and replacement intervals to maintain safety and performance.

- Diagnostic Scan: Use an OBD-II tool to read EPB fault codes.

- Pad Thickness Check: Replace pads below 3 mm.

- Wiring Inspection: Repair or replace any corroded or damaged connectors immediately.

- Functional Test: Ensure the EPB engages and releases within 2–4 seconds.

Conclusion

Understanding how your electric parking brake works and knowing the early warning signs of trouble are key to maintaining safe, smooth vehicle operation. Regular inspections and timely repairs help prevent costly failures and ensure optimal performance. For best results, consult a professional technician and choose FBK braking products specifically engineered for your vehicle’s electric parking brake system.