Understanding the Differences Between High-Quality and Budget Back Brake Pads

When it comes to vehicle safety, the quality of your back brake pads is critical. As a brand with decades of experience in braking solutions, we have seen how the choice between high-quality and budget brake pads impacts both performance and long-term reliability. While budget options may look appealing due to their lower cost, they often compromise on materials and manufacturing processes, leading to inconsistent braking and faster wear.

High-quality back brake pads, particularly those developed through advanced in-house formulations and rigorous laboratory testing, offer superior stopping power and longevity. Our experience in collaborating with test laboratories has shown that premium pads maintain their effectiveness across a wider range of temperatures and conditions, ensuring your safety even in demanding scenarios.

- Recommended minimum thickness: 3 mm before replacement.

- Typical high-quality pad lifespan: 30,000–60,000 km depending on driving habits.

- Operating temperature range for premium pads: -30°C to 400°C.

- Stopping distance variance: Budget pads may increase stopping distance by up to 15%.

Warning Signs

- Unusual noises such as grinding or squealing during braking.

- Noticeable decrease in braking responsiveness.

- Brake warning light illuminated on the dashboard.

Performance and Safety Considerations of Back Brake Pads

Performance is not just about how quickly you can stop, but also how consistently your brakes respond under repeated use. High-quality back brake pads are manufactured with precise tolerances and advanced materials, resulting in less brake fade and better performance in emergency stops. Budget alternatives may not undergo the same level of laboratory testing or quality control, which can lead to unpredictable results.

Safety is at the core of our philosophy, built on years of refining friction materials and manufacturing processes. Reliable back brake pads ensure even wear, minimize the risk of rotor damage, and maintain performance in both wet and dry conditions. Choosing quality over cost means investing in your peace of mind every time you drive.

- Brake fade threshold: Premium pads typically resist fade up to 350°C.

- Rotor wear rate: High-quality pads can extend rotor life by 20–30%.

- Consistent braking: Premium pads maintain stable friction levels for 95% of their lifespan.

- Reduced dust: Quality pads produce up to 50% less brake dust compared to budget brands.

Warning Signs

- Vibration or pulsing in the brake pedal during application.

- Visible scoring or grooves on the brake rotor surface.

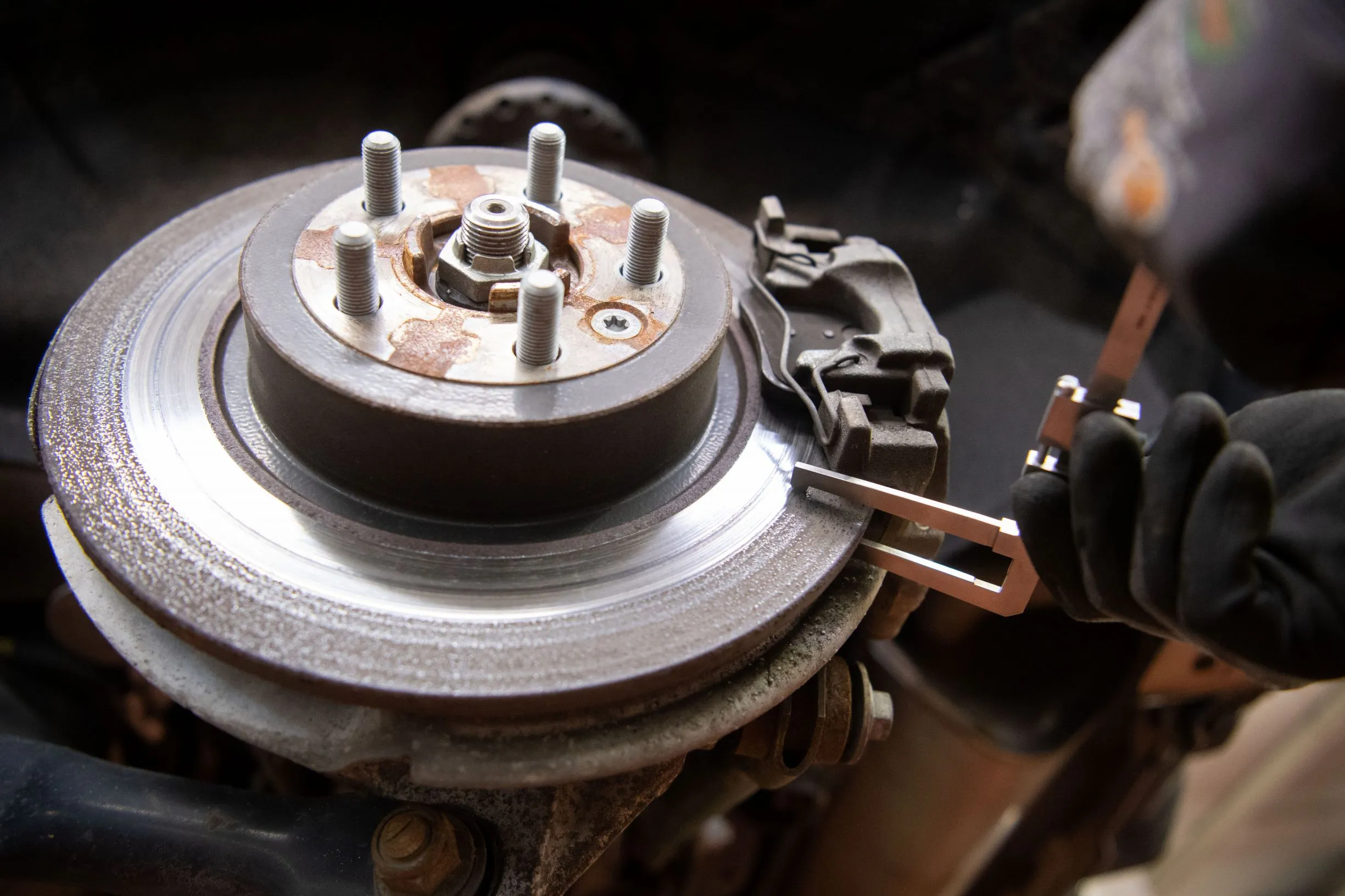

How to Inspect and Maintain Your Back Brake Pads

Regular inspection and timely maintenance of back brake pads are essential for optimal braking performance. Begin by visually checking the pad thickness through the wheel spokes or by removing the wheel if necessary. Pads should be replaced before they reach the minimum thickness recommended by the manufacturer, which is usually about 3 mm. Monitoring for uneven wear can also help you spot potential issues with calipers or rotors early on.

Our experience with advanced manufacturing and in-house quality control highlights the importance of following a consistent maintenance schedule. Ignoring early signs of wear or damage can lead to more expensive repairs and compromise your safety on the road.

- Check pad thickness: Every 10,000 km or during routine servicing.

- Replace both sides: Always change pads on both rear wheels at the same time.

- Listen for noise: Squealing or grinding often indicates immediate attention is needed.

- Inspect rotors: Check for grooves or discoloration during pad replacement.

Common Problems with Budget Back Brake Pads

Budget back brake pads often present a range of issues linked to inferior materials and less stringent production standards. Our collaboration with independent test laboratories has revealed that these pads can suffer from accelerated wear, higher noise levels, and inconsistent braking performance. Over time, this can lead to increased maintenance costs and reduced safety margins.

It is not uncommon for budget pads to generate excessive dust and cause premature rotor wear, resulting in a rough or pulsing feel in the brake pedal. In the long run, the cost savings from choosing budget options are often outweighed by the need for more frequent replacements and potential damage to other braking components.

- Typical budget pad lifespan: 12,000–25,000 km.

- Noise complaints: Up to 35% higher incidence compared to premium pads.

- Dust generation: Can be double that of high-quality pads.

- Risk of rotor damage: Significantly increased with hard or contaminated friction materials.

Conclusion

Choosing high-quality back brake pads is essential for ensuring safety, consistent performance, and long-term value. Years of expertise, advanced manufacturing, and rigorous testing all contribute to products you can trust. Make it a habit to inspect your brakes regularly and consult a professional or select the correct FBK product for your vehicle to keep your journeys safe and smooth.