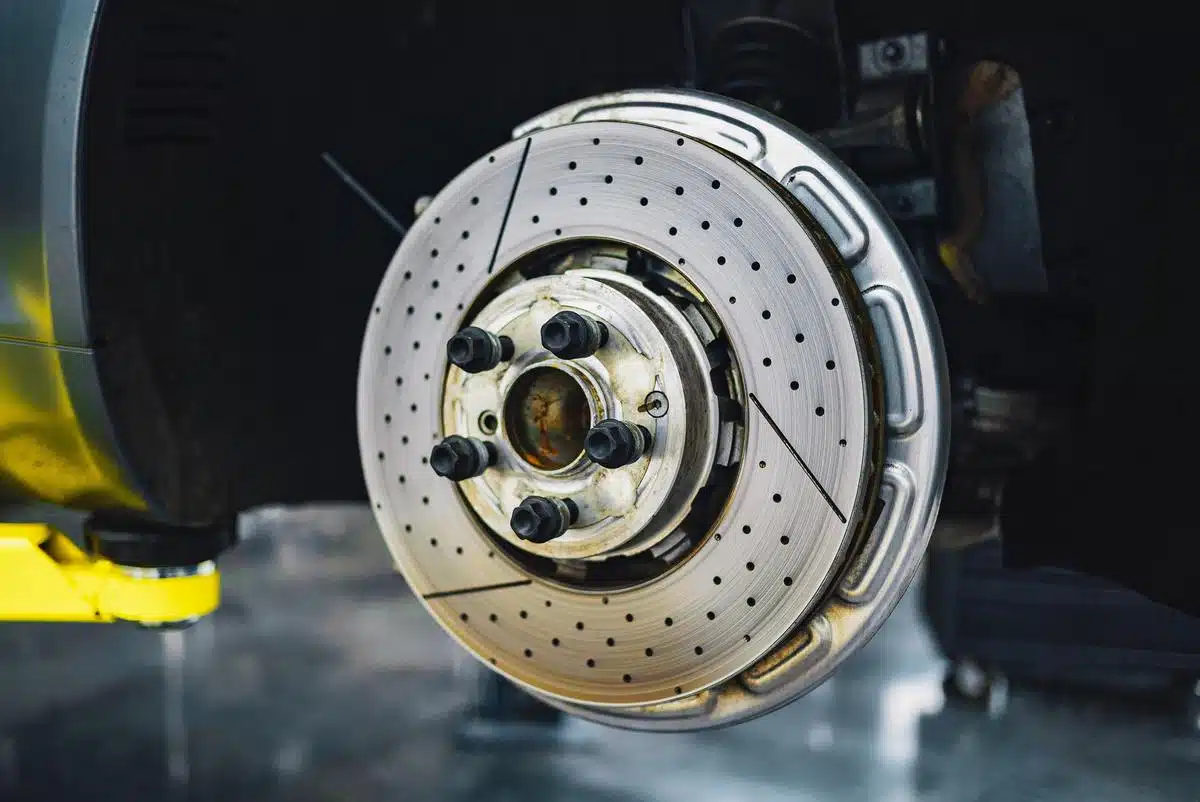

Brake rotor packaging plays a critical role in maintaining the integrity of these heavy, precision-machined components. Made of cast iron, rotors are vulnerable to two major threats during shipping and storage: corrosion (rust) and physical deformation (warping or runout).

A damaged rotor before installation means guaranteed performance failure, high warranty costs, and unsatisfied customers.

The Two Main Enemies of a New Brake Rotor

| Risk Factor | Description | Primary Cause of Damage |

|---|---|---|

| Corrosion (Rust) | Oxidation of the iron surface creates uneven high spots. Even a thin film of rust can lead to brake judder upon installation. | Moisture and humidity in the environment. |

| Physical Damage | Warping, bowing, or deep gouges on the friction surface. Even a 0.002-inch change can cause pedal pulsation. | Poor packaging and improper stacking during storage. |

Phase 1: Packaging Practices to Protect the Rotor Finish

The main purpose of brake rotor packaging is to safeguard the braking surface from moisture and physical impact until it reaches the mechanic’s bench.

1. Anti-Corrosion Protection

Because cast iron rusts quickly, effective packaging must create a sealed, dry microclimate around the rotor.

-

Vapor Corrosion Inhibitor (VCI) Wraps: Industry-standard for rust prevention. VCI-treated paper or plastic bags release vapor molecules that form an invisible shield on the metal surface—protecting it without messy oil coatings.

-

Desiccants: For long-term or high-humidity routes, add a small silica gel packet to absorb moisture inside the sealed package.

-

Protective Coating: Premium rotors may include a light oil, zinc, or polymer coating. The packaging must preserve this layer to prevent corrosion during transit.

2. Physical Protection and Cushioning

Brake rotors are heavy with sharp edges, requiring durable boxes and secure cushioning to prevent movement or surface contact.

-

High-Strength Corrugated Boxes: Double-wall corrugated cardboard rated for the rotor’s weight helps prevent crushing or bending.

-

Custom Inserts and Padding: Foam, molded pulp, or firm cardboard inserts prevent movement and protect the friction surface from scuffing.

-

Edge Protection: Cover sharp edges with thick plastic guards or padding to stop cuts through the wrap or box.

Phase 2: Safe Storage to Prevent Warping

After packaging, the main risk becomes long-term deformation. Proper storage conditions prevent bowing, bending, or condensation damage.

The Stacking Dilemma: Horizontal or Vertical?

| Storage Method | Recommendation | Risk & Mitigation |

|---|---|---|

| Horizontal (Stacked) | Recommended when kept in sturdy boxes. | Risk: Lower rotors may warp under weight. Mitigation: Respect stacking limits and use shelves, not floors. |

| Vertical (Standing) | Not ideal for general storage. | Risk: May tip or deform the hat section. Mitigation: Use specialized racks if necessary. |

| Environment | Keep cool, dry, and clean (RH below 60%). | Risk: Humidity causes rust; temperature changes cause condensation. Mitigation: Maintain stable, climate-controlled conditions. |

Key Storage Guidelines

-

Keep Rotors Flat and Immobile: Prevent pressure points that may distort the metal.

-

Avoid Direct Sunlight: Sunlight raises internal temperatures, causing condensation inside sealed packaging.

-

Rotate Inventory: Follow the FIFO (First-In, First-Out) method to minimize long-term storage exposure. Rotors should ideally be used within a few years.

The Final Verdict: Quality Starts with Packaging

The service life of a brake rotor begins the moment it is packaged, not when it’s installed. Poor quality control in brake rotor packaging and storage directly leads to premature brake failure, vibration complaints, and costly returns.

For manufacturers, investing in VCI technology, robust corrugated boxes, and strict stacking standards is not an expense—it’s a safeguard. Proper packaging reduces damage, lowers return rates, and strengthens brand trust in safety and reliability.

Always inspect both the rotor and its packaging upon arrival. If the box is torn, wet, or crushed, the integrity of the part is already compromised.